Equipment & devices

Production aids for your process

The equipment is controlled using Siemens, Wago or in-house programmed software.

We are also happy to support you with our knowledge for your assembly and component production. From purely manual devices to fully automated systems, with evaluation and documentation of various process parameters, we can support you.

Tell us your requirements and we will find a solution together. You will be assigned a contact person who will support you throughout the entire project.

Equipment and fixture construction in detail

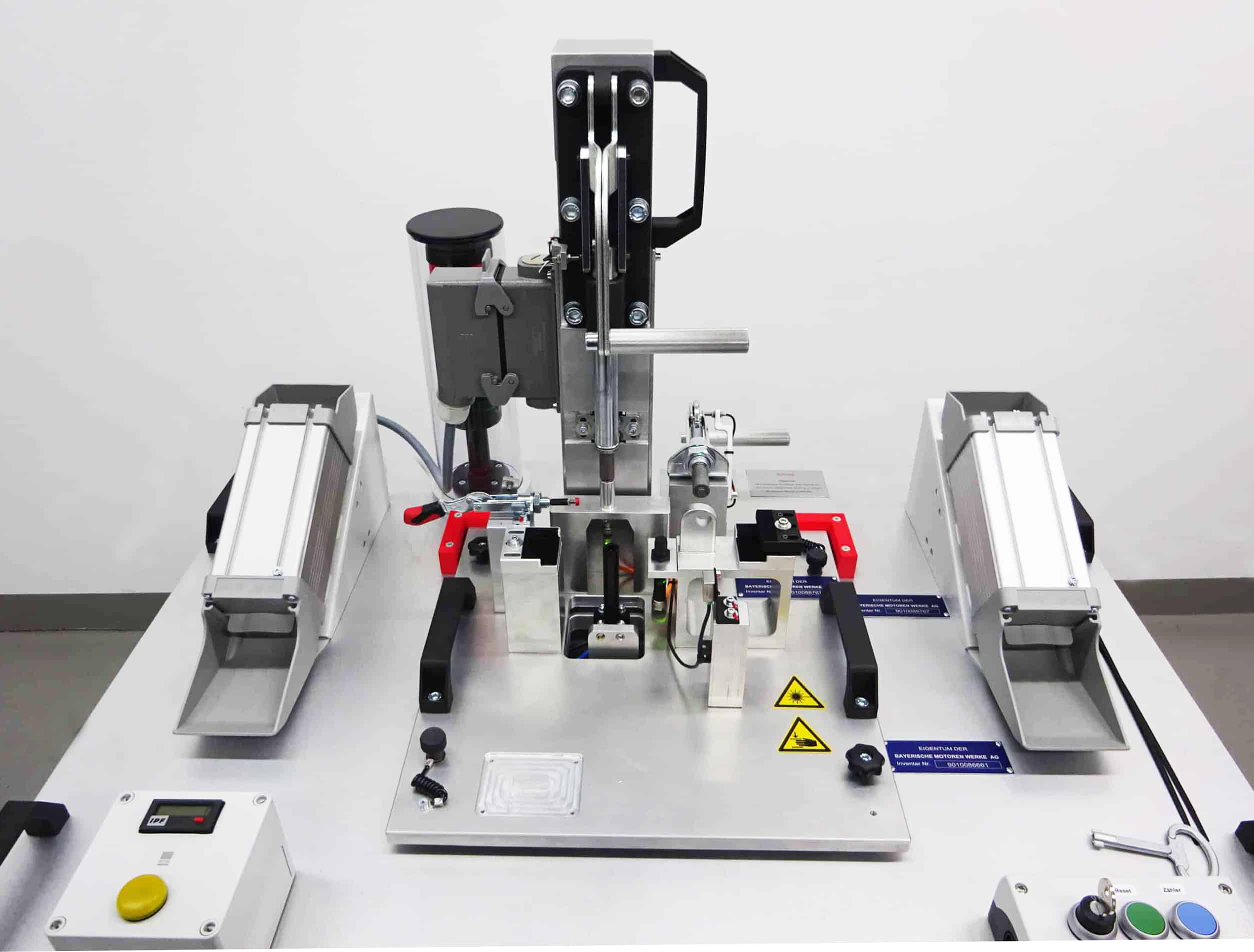

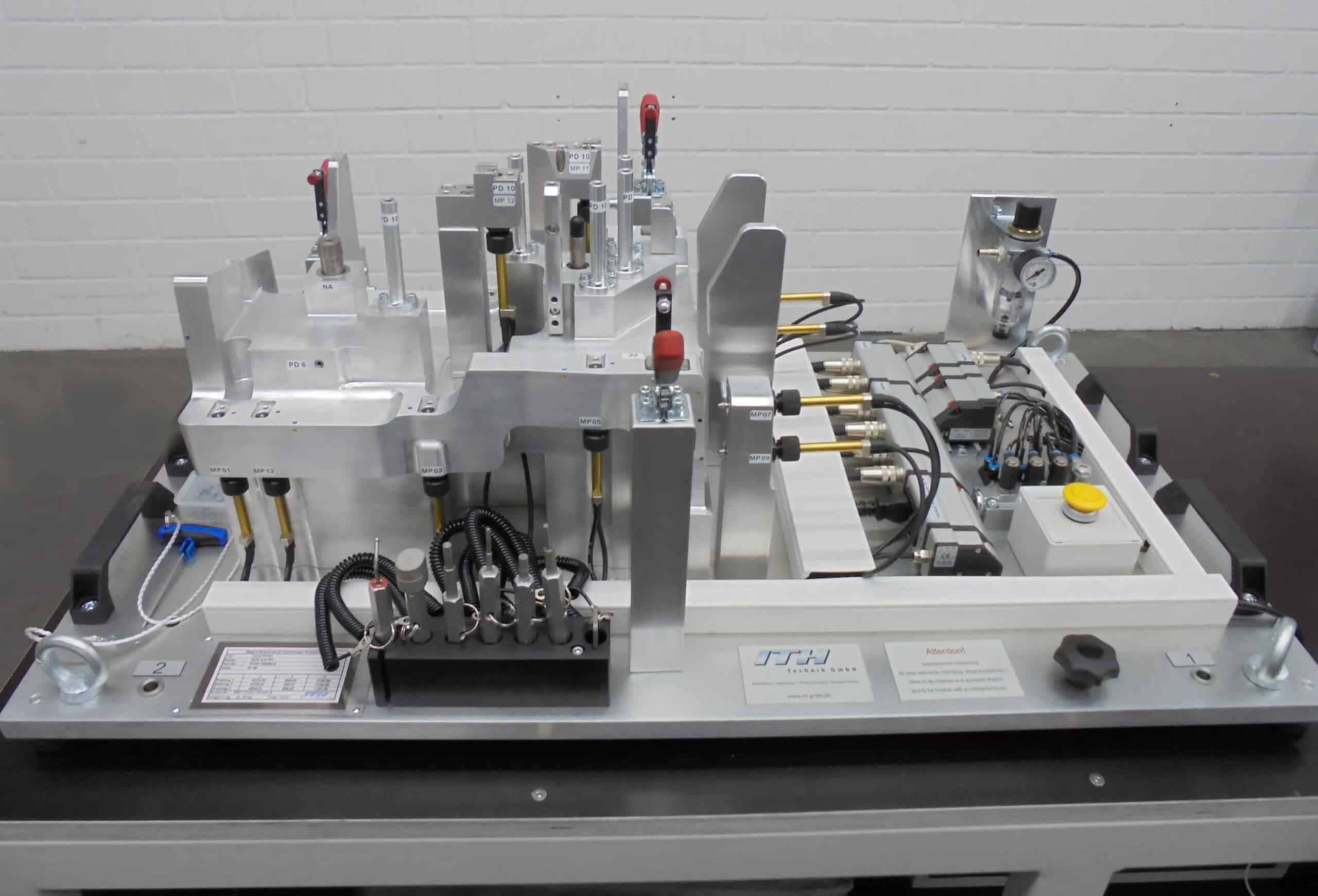

1. Assembly & Auxiliary Devices

To support your assembly processes, we design and manufacture equipment tailored to your needs. These ensure process-accurate positioning and safe and efficient assembly.

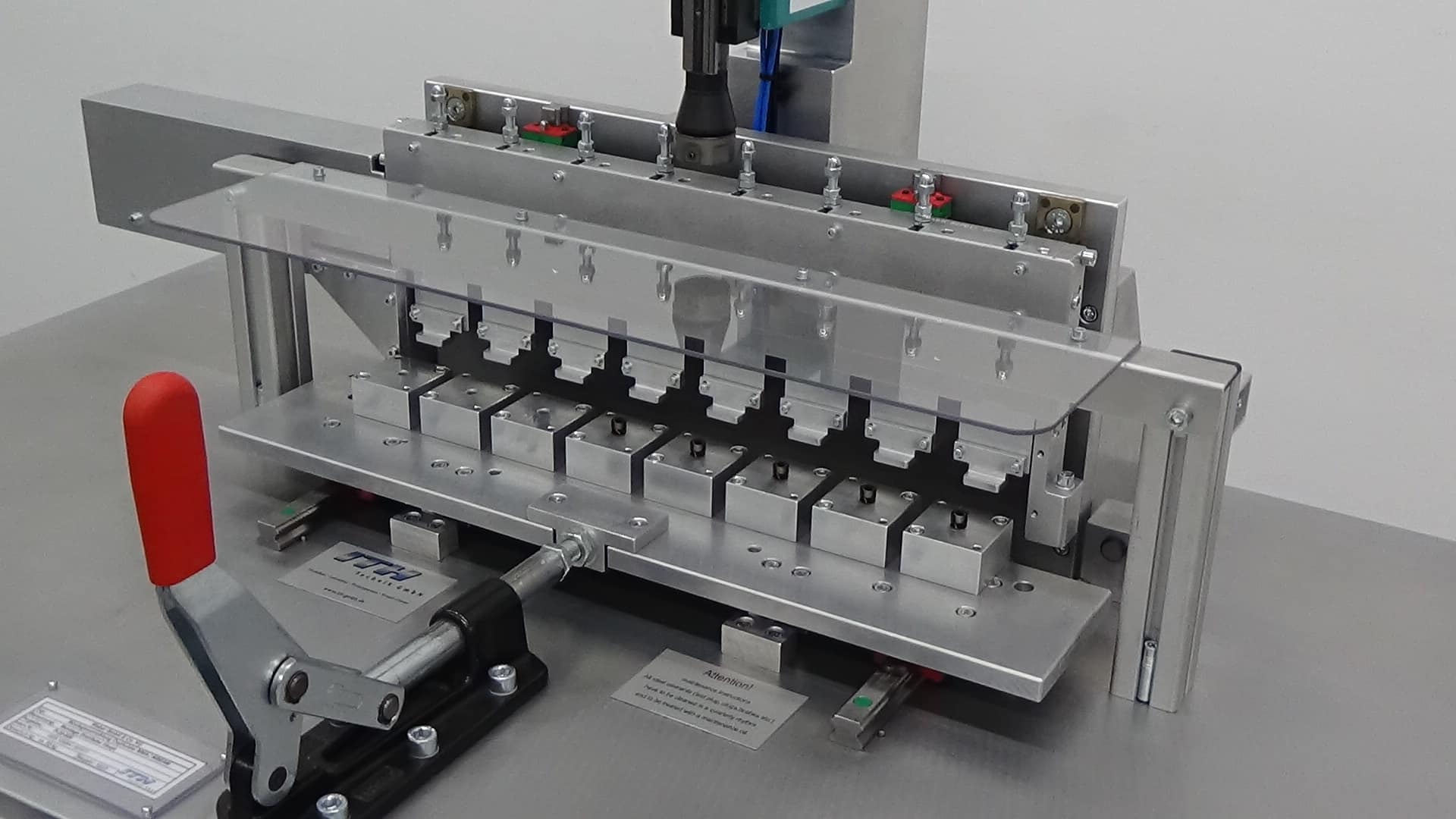

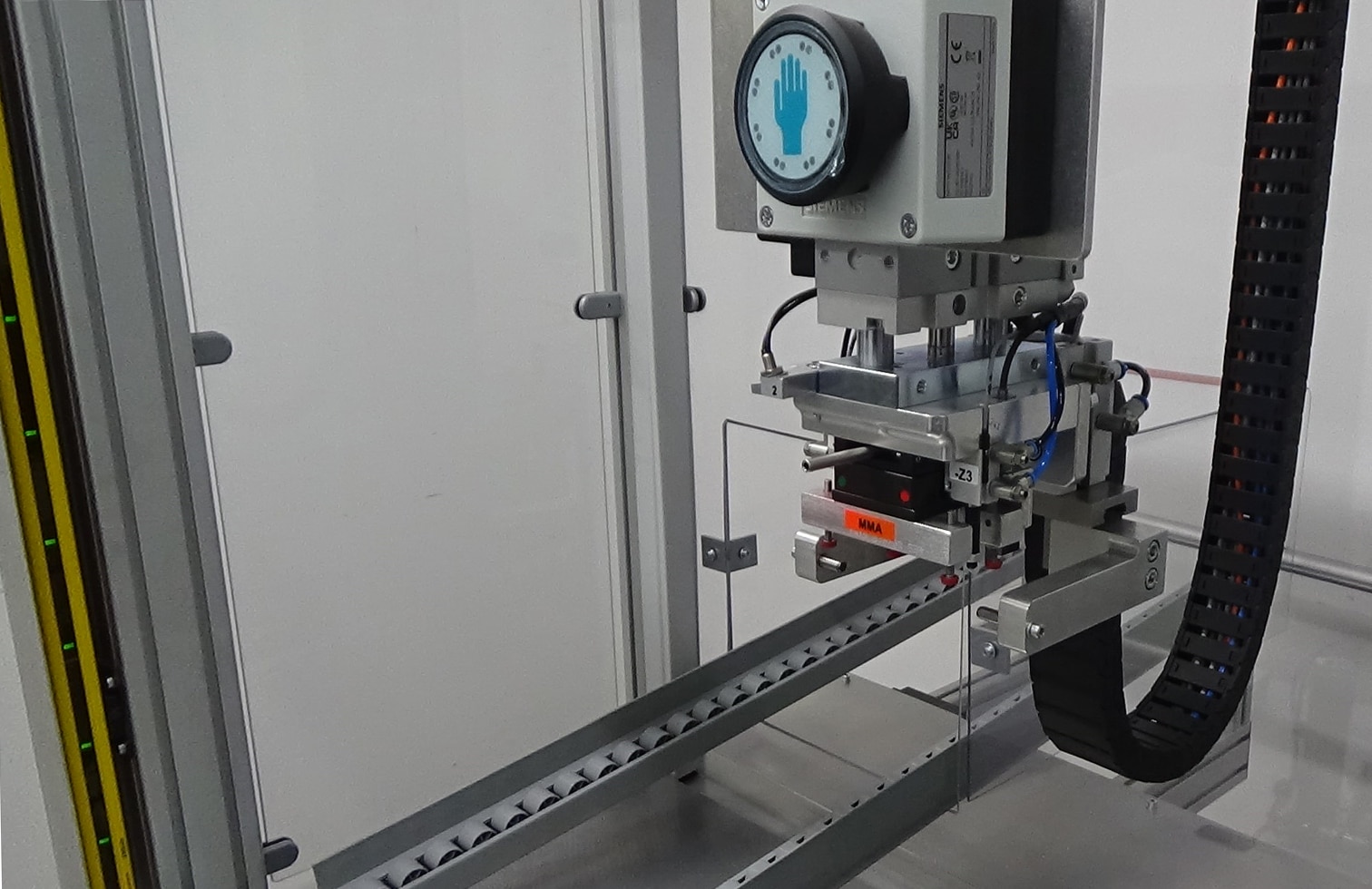

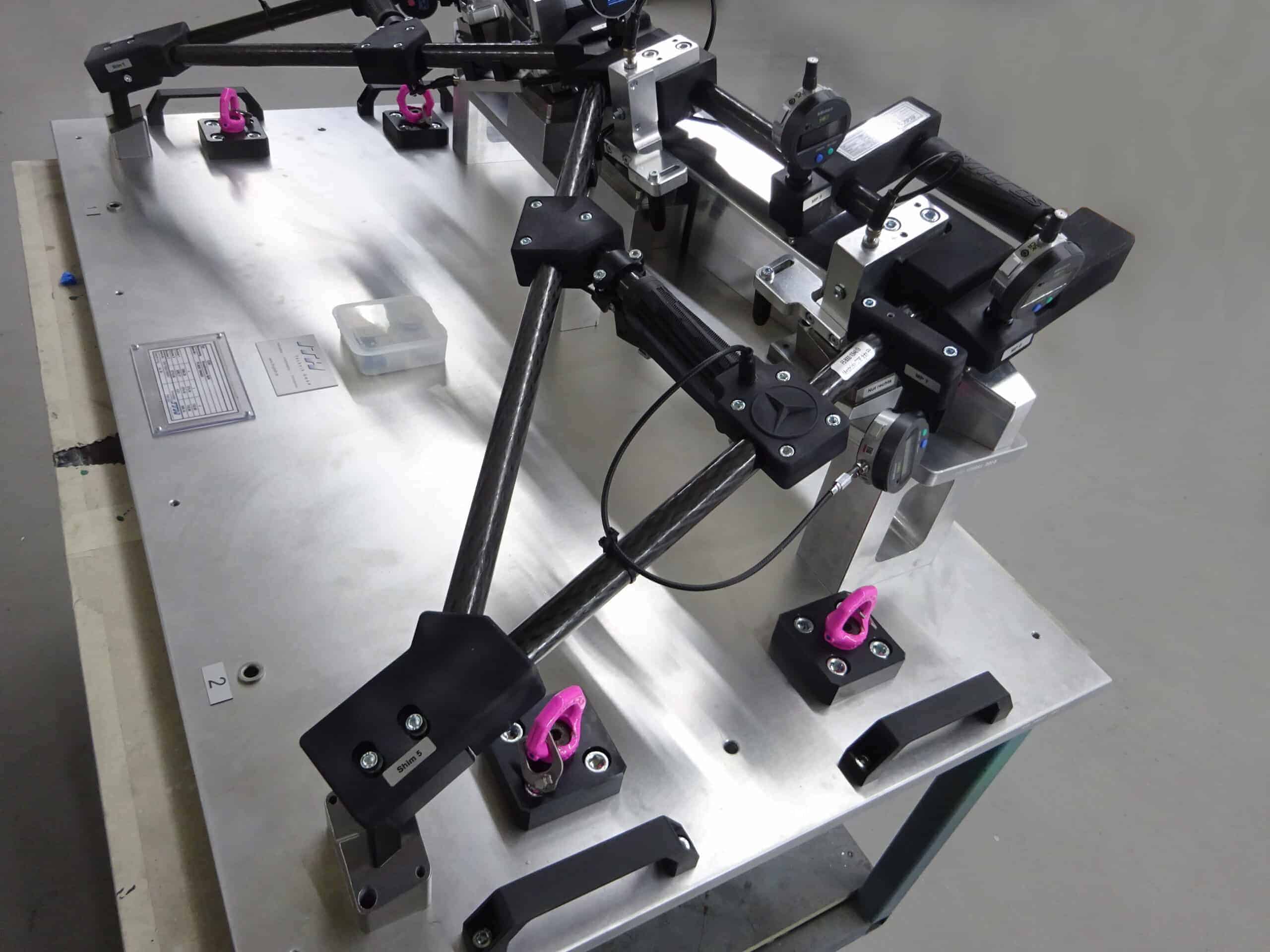

2. Screwing Devices

We support you with the design and manufacture of screwdriving fixtures for your processes. Our solutions range from simple screwdriver holding fixtures with cable balancers to torque holding fixtures with carbon telescopic arms or fixed guide systems. Integration into your existing production systems included.

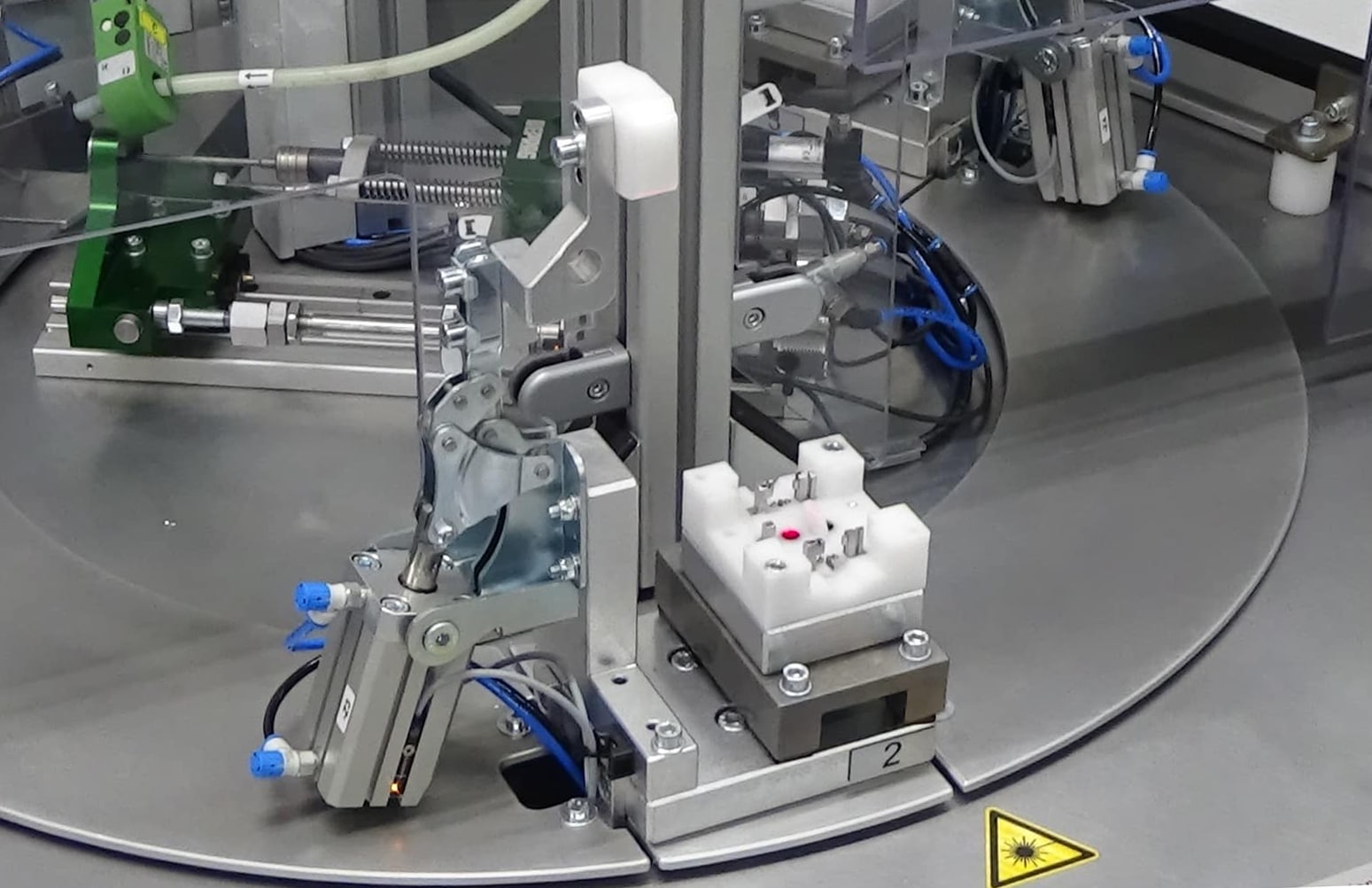

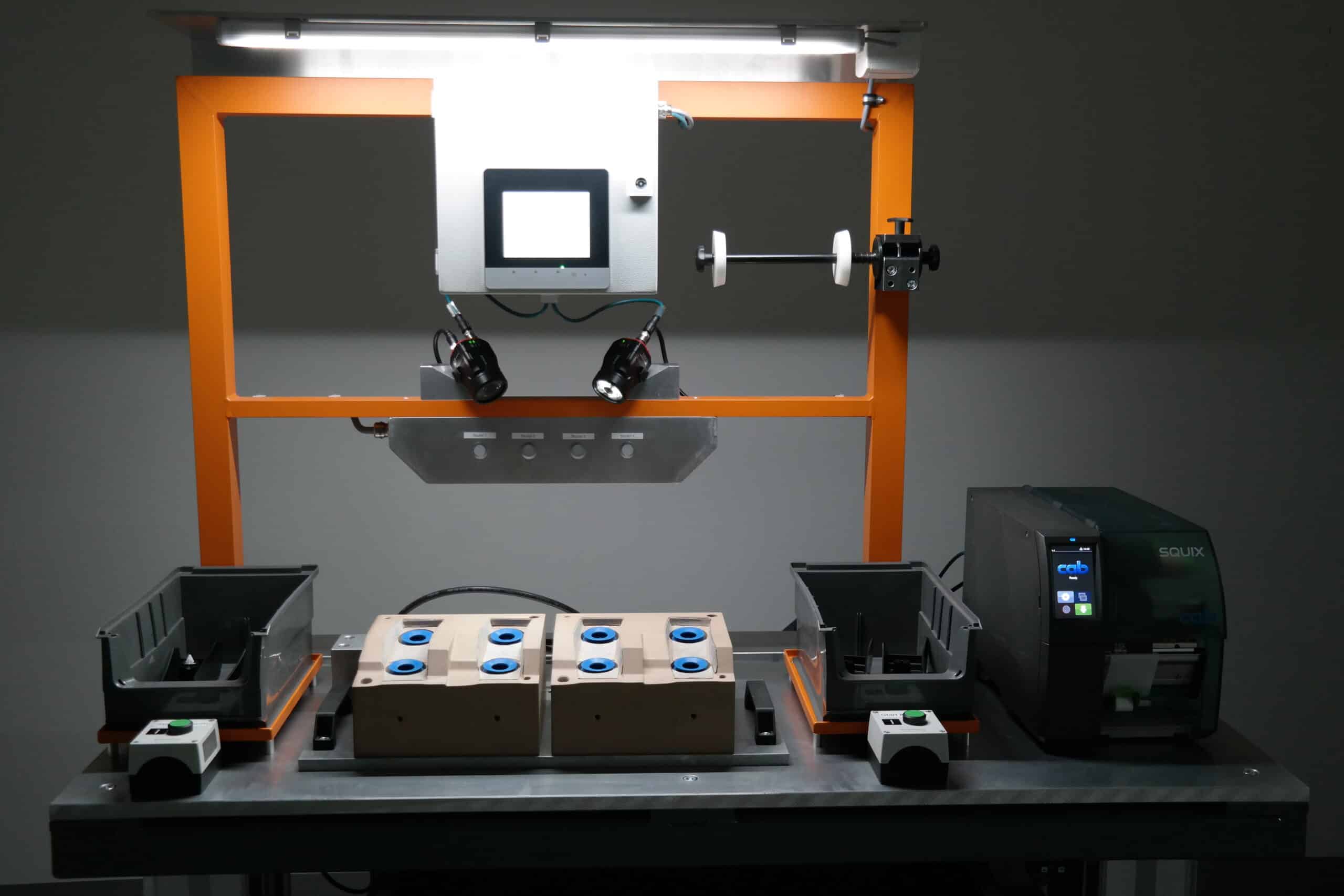

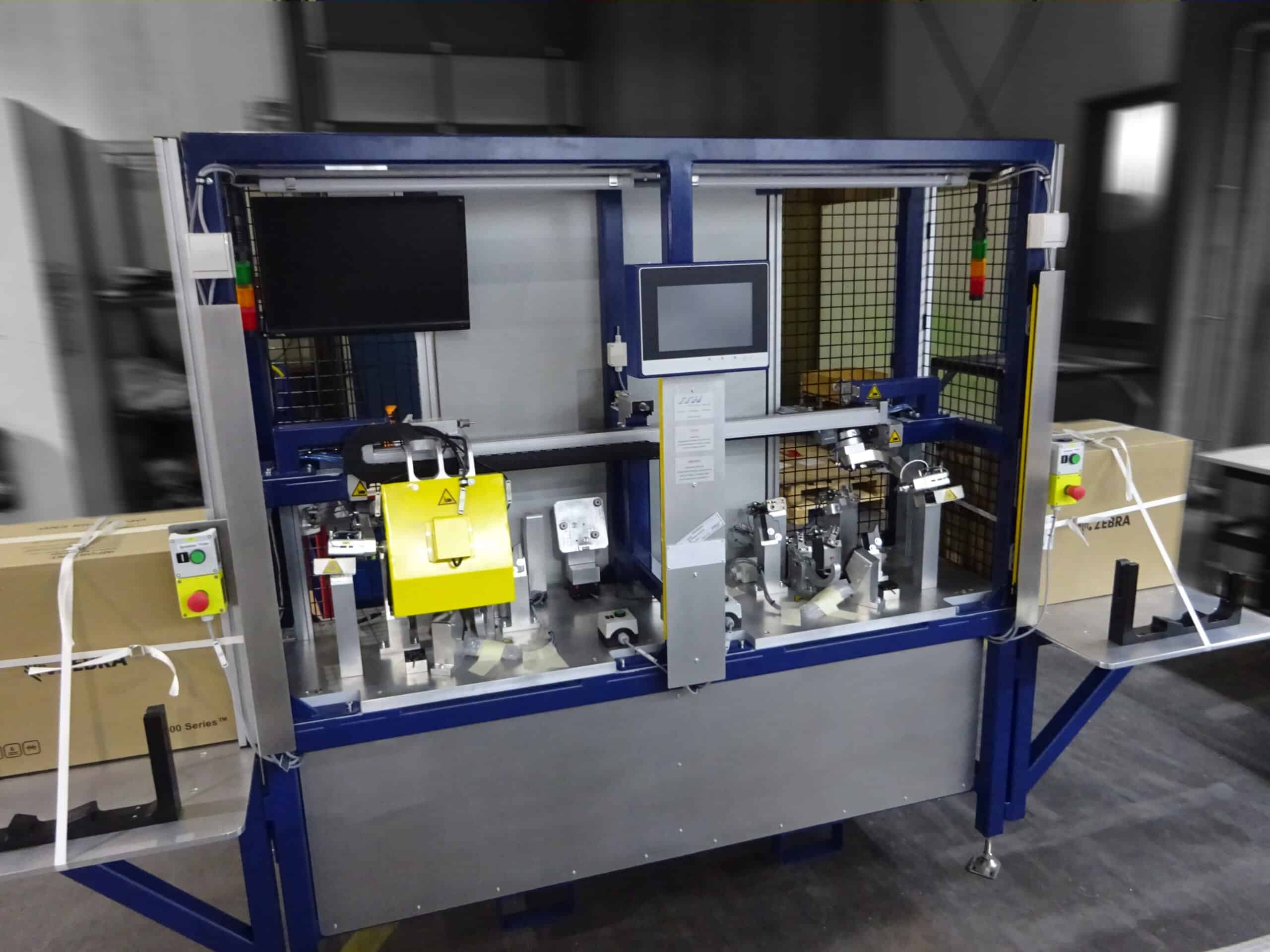

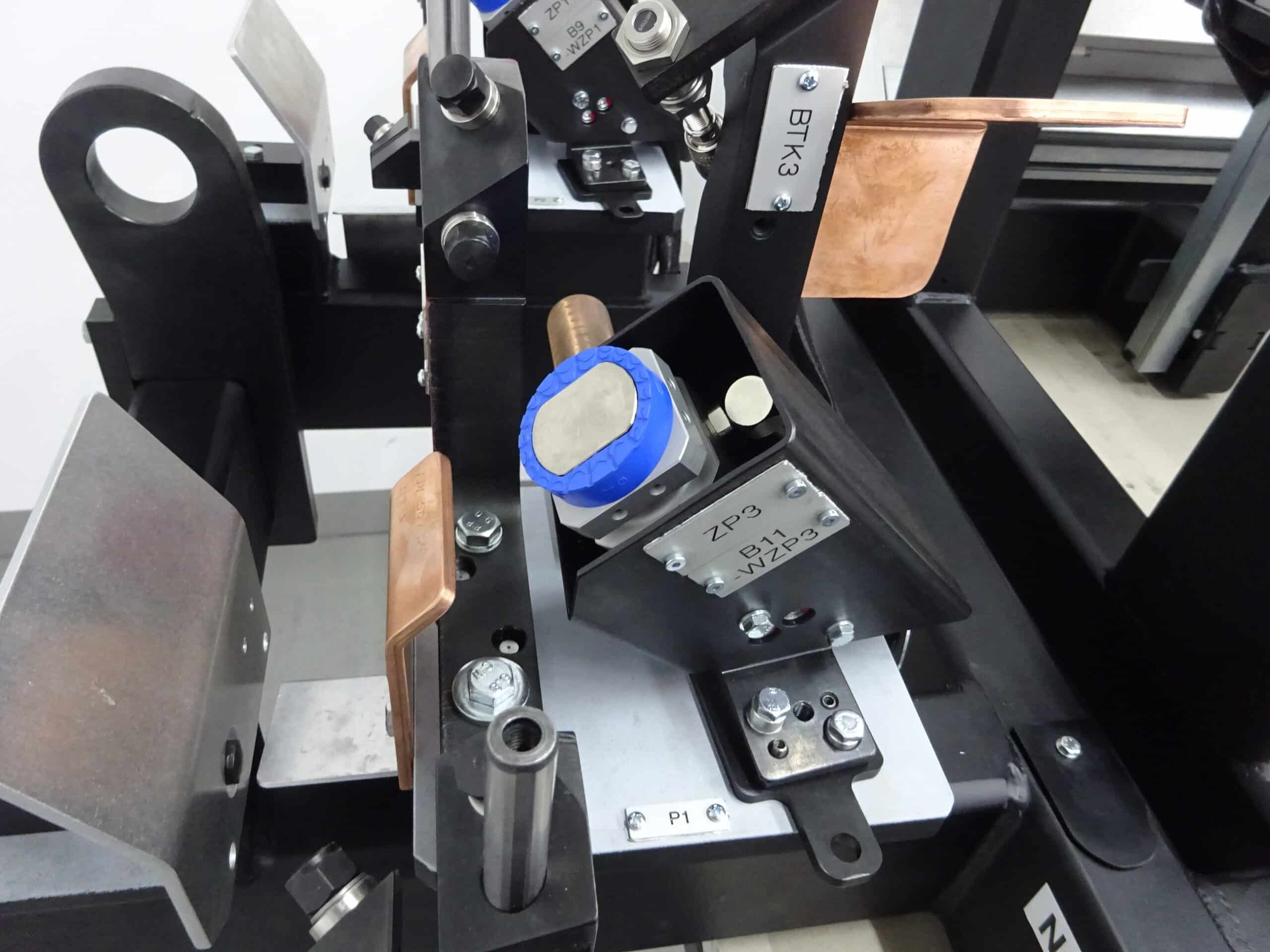

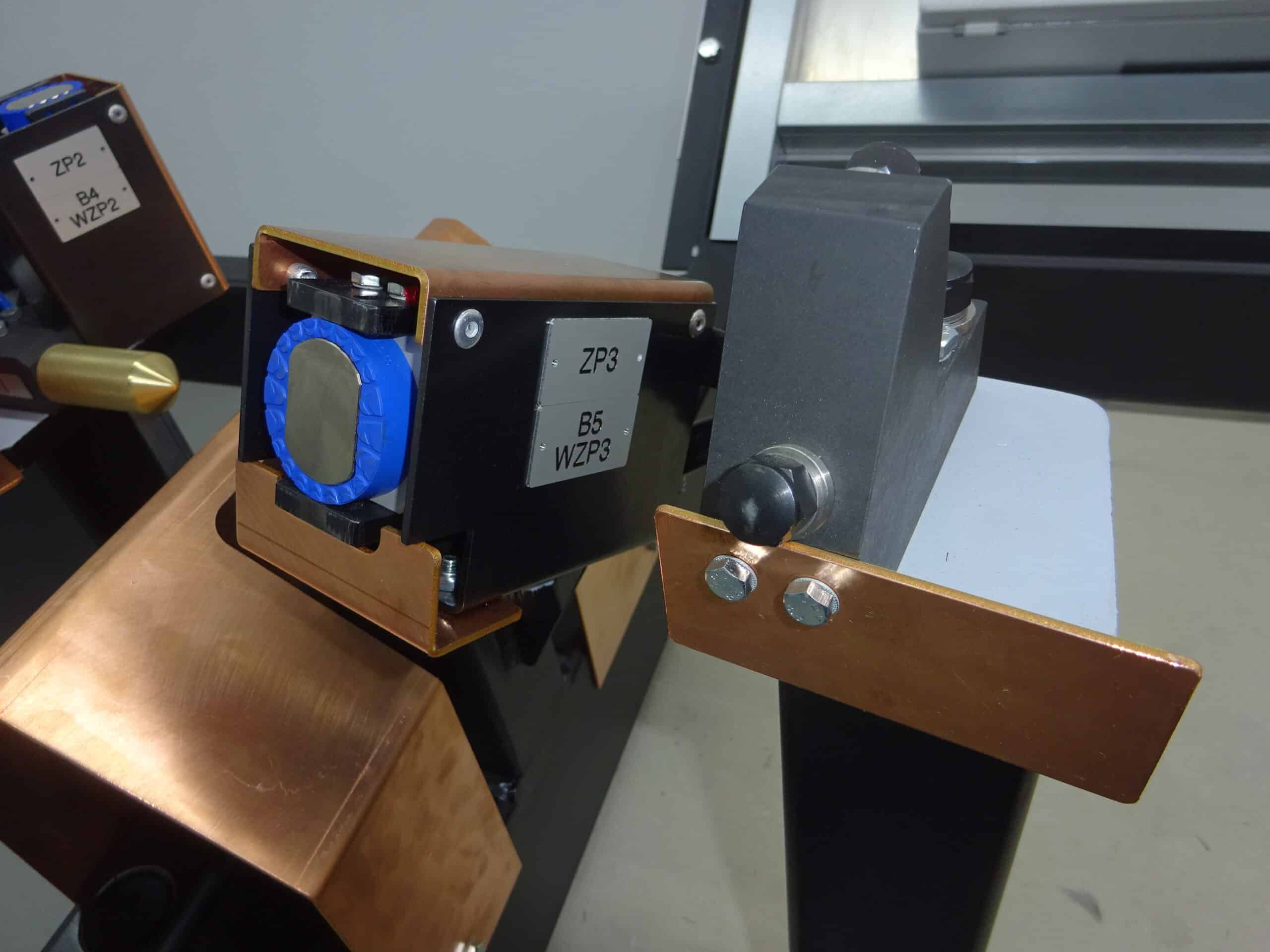

3. Automated Test Systems – EOL

We implement particularly high requirements for cycle times and complex test procedures, which should be automated, reliable and free of errors, in automated test systems.

Various test requirements such as length, position and thickness measurements as well as torques, acoustic values and force recordings are recorded and evaluated.

This is achieved by using touch probes, initiators, laser sensors and camera systems.

The execution of the inspection, such as recording and documentation, is carried out e.g. PLC-controlled and automated in the form of visualization, label printing or transfer to QDA systems.

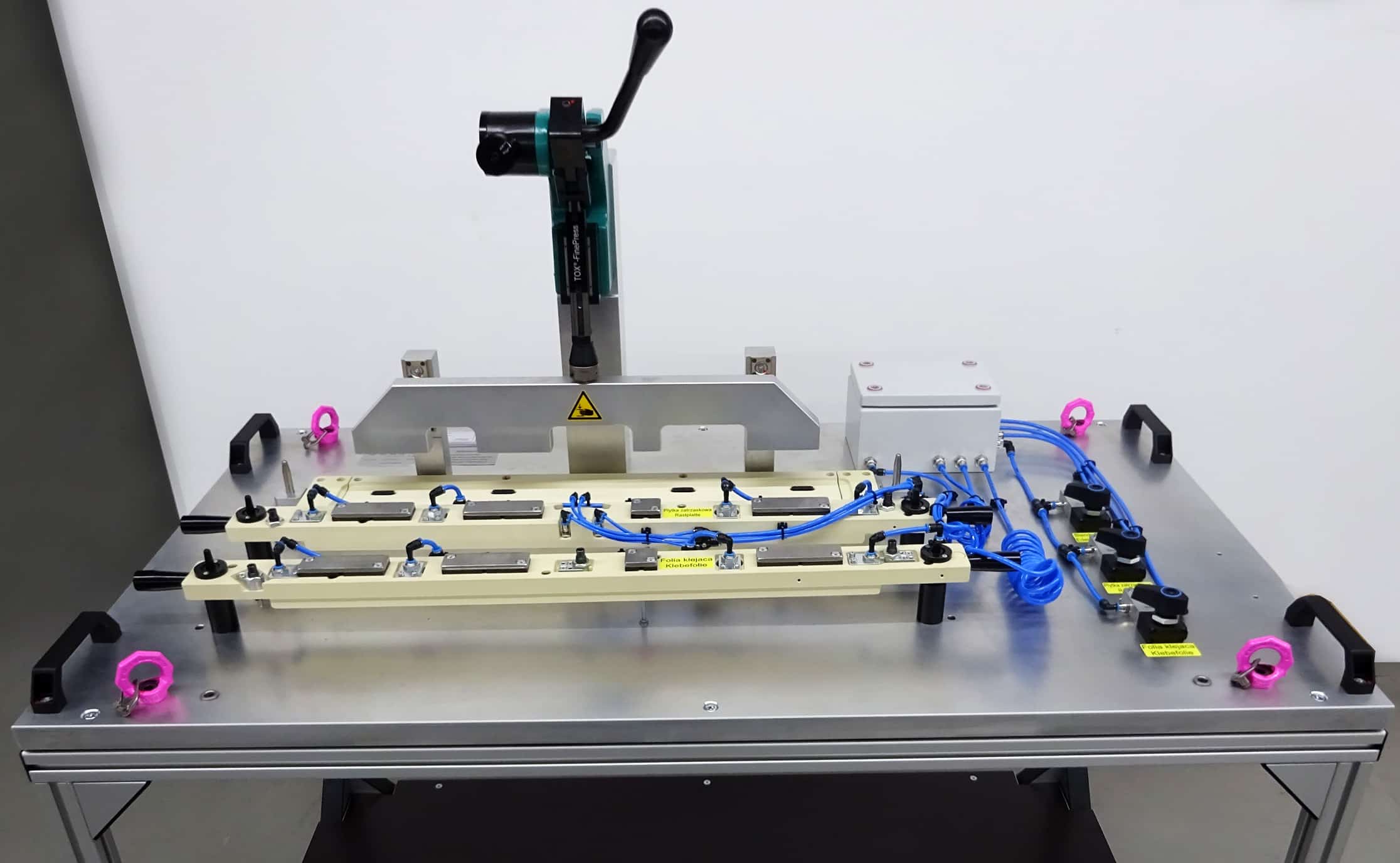

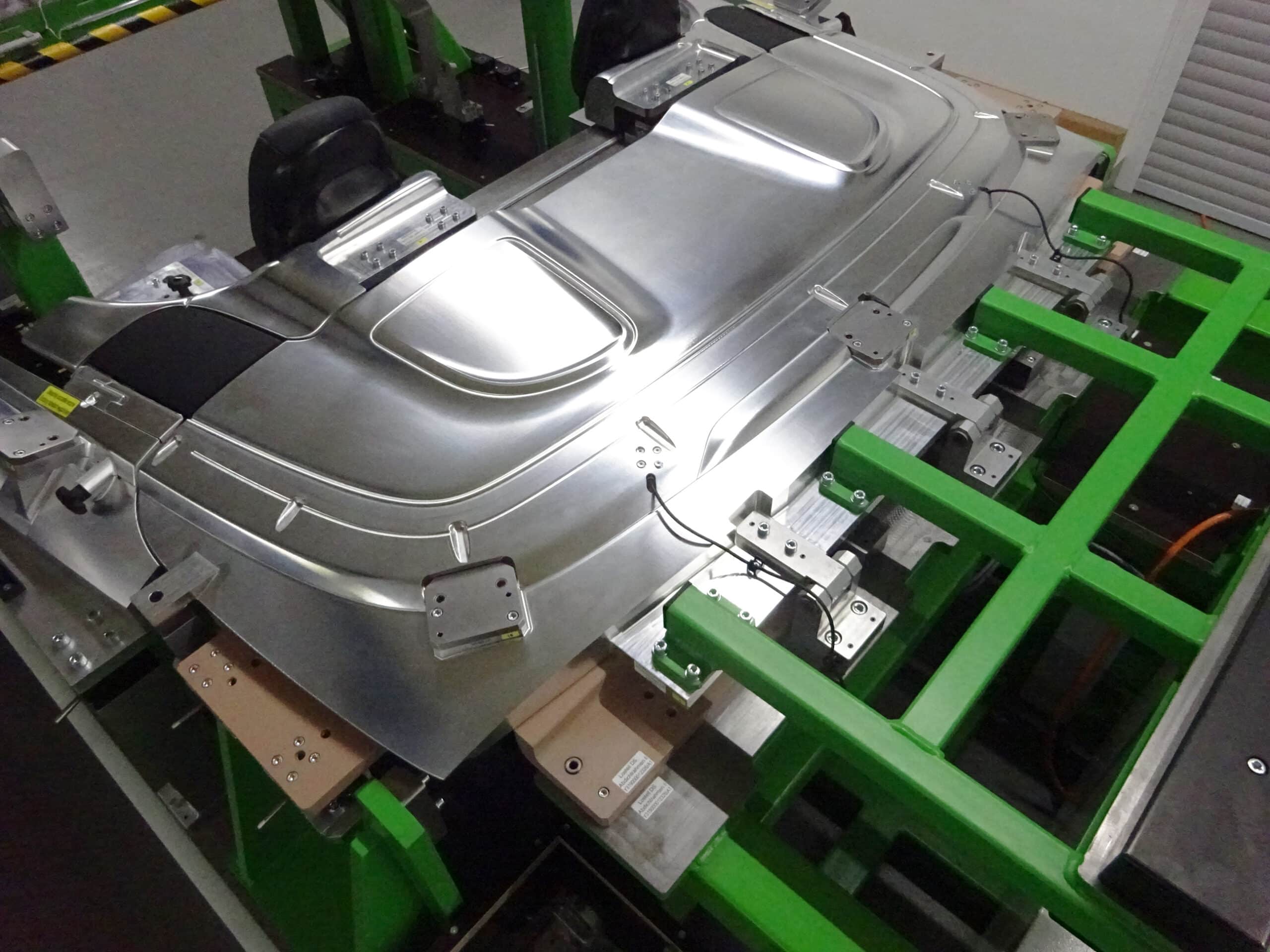

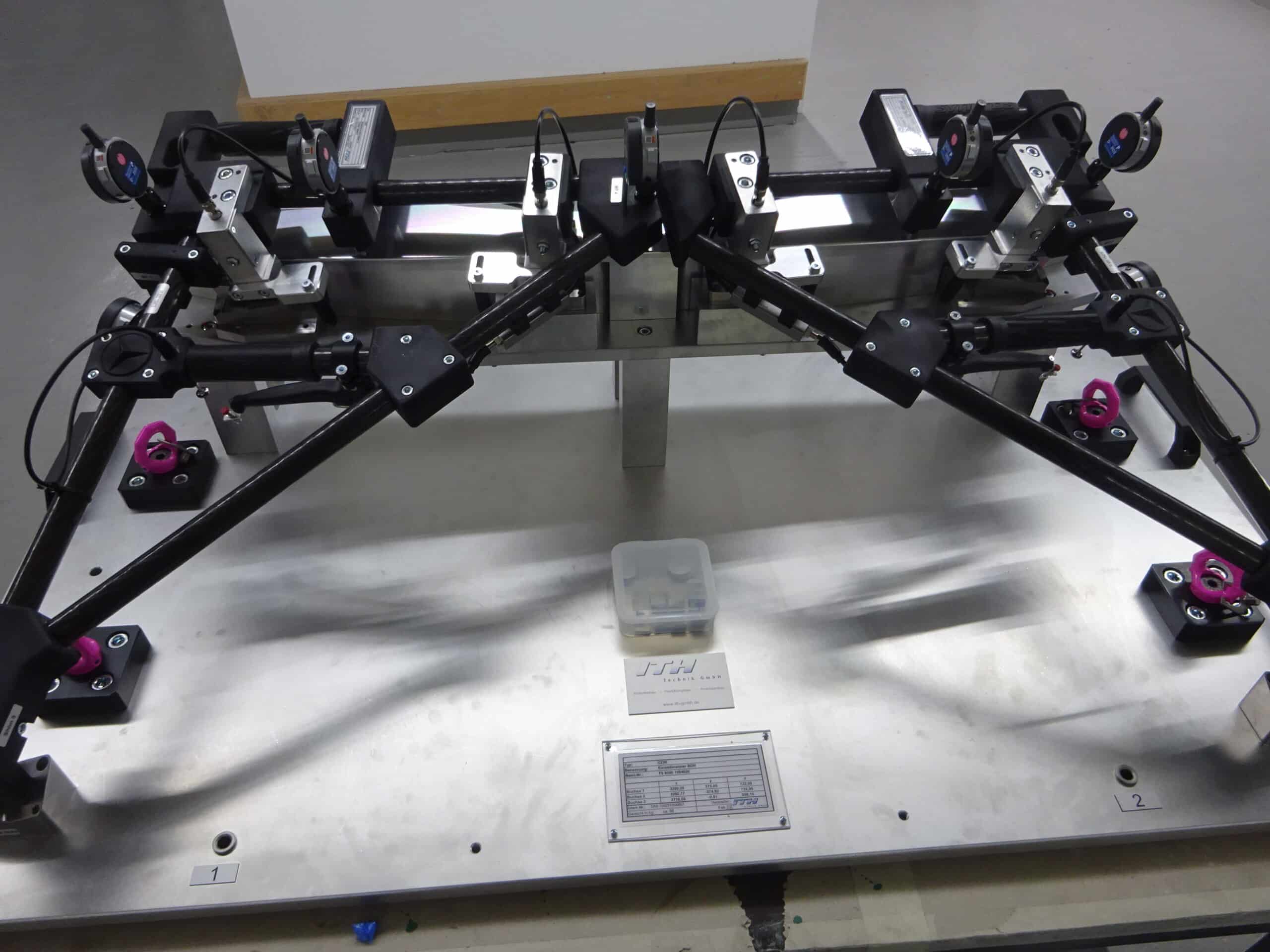

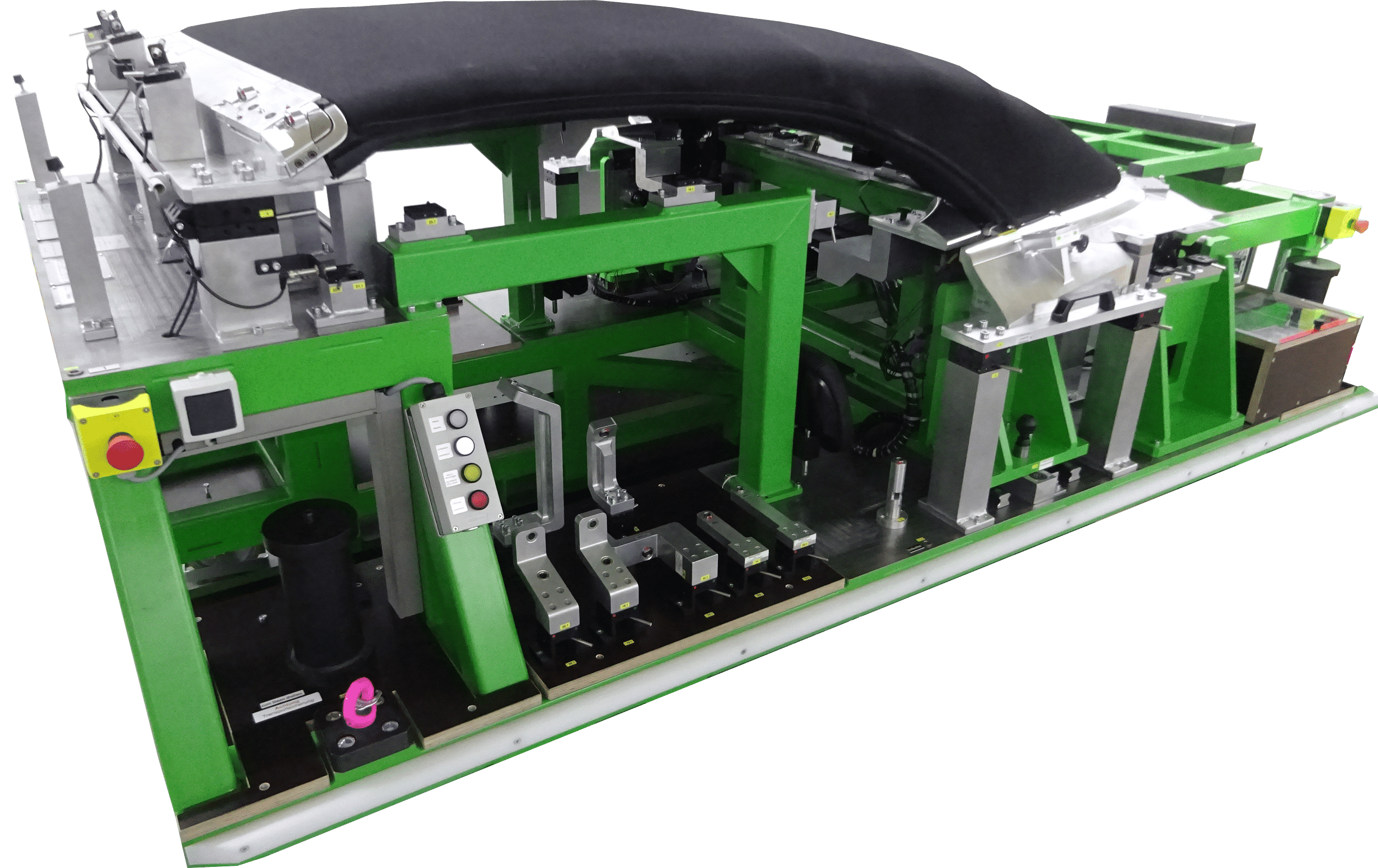

4. Special Machine Solutions

From manually loaded and clamped fixtures for manual welding to semi-automated solutions and robot-loaded fixtures with electrically controlled, pneumatic clamping concepts for inline production.

Our fixtures fix and position your components and thus form a solid basis for your production process. The fixtures can be supplemented with additional functions, such as embossing units.