Test equipment construction

Safeguarding your process

Our test equipment ensures that your quality targets are met: measuring fixtures, control gauges, master blocks and cubing models.

With experience, craftsmanship and modern manufacturing processes, we produce everything in-house, from design to sampling. We pursue efficient processes with great flexibility for your requirements and innovative solutions.

The visible and measurable quality of our test equipment helps you to safeguard your processes.

Test equipment construction in detail

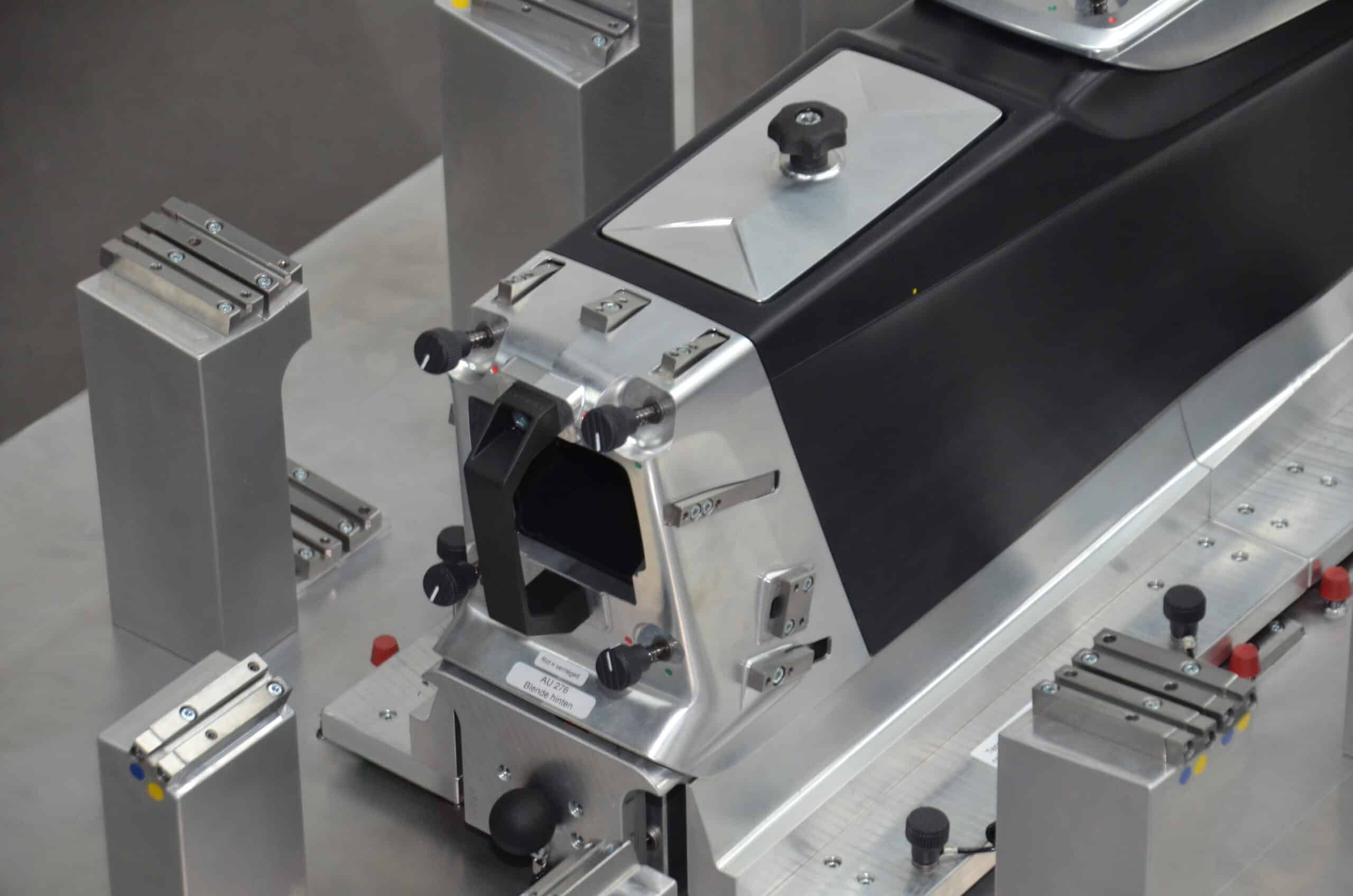

1. Measurement recordings

We manufacture the measuring mounts to safeguard your component measurement. Adapted to your requirements, both for tactile and optical measuring tasks. The structure is made of aluminum, CFRP or steel. – As a complete fixture or in modular design for use on perforated grid plates. We have continuously developed our designs to ensure ease of modification and optimized handling. Our measuring fixtures based on a CFRP structure represent the latest level of innovation. Lightweight and efficient – for quick conversion of the measuring station or change of location.

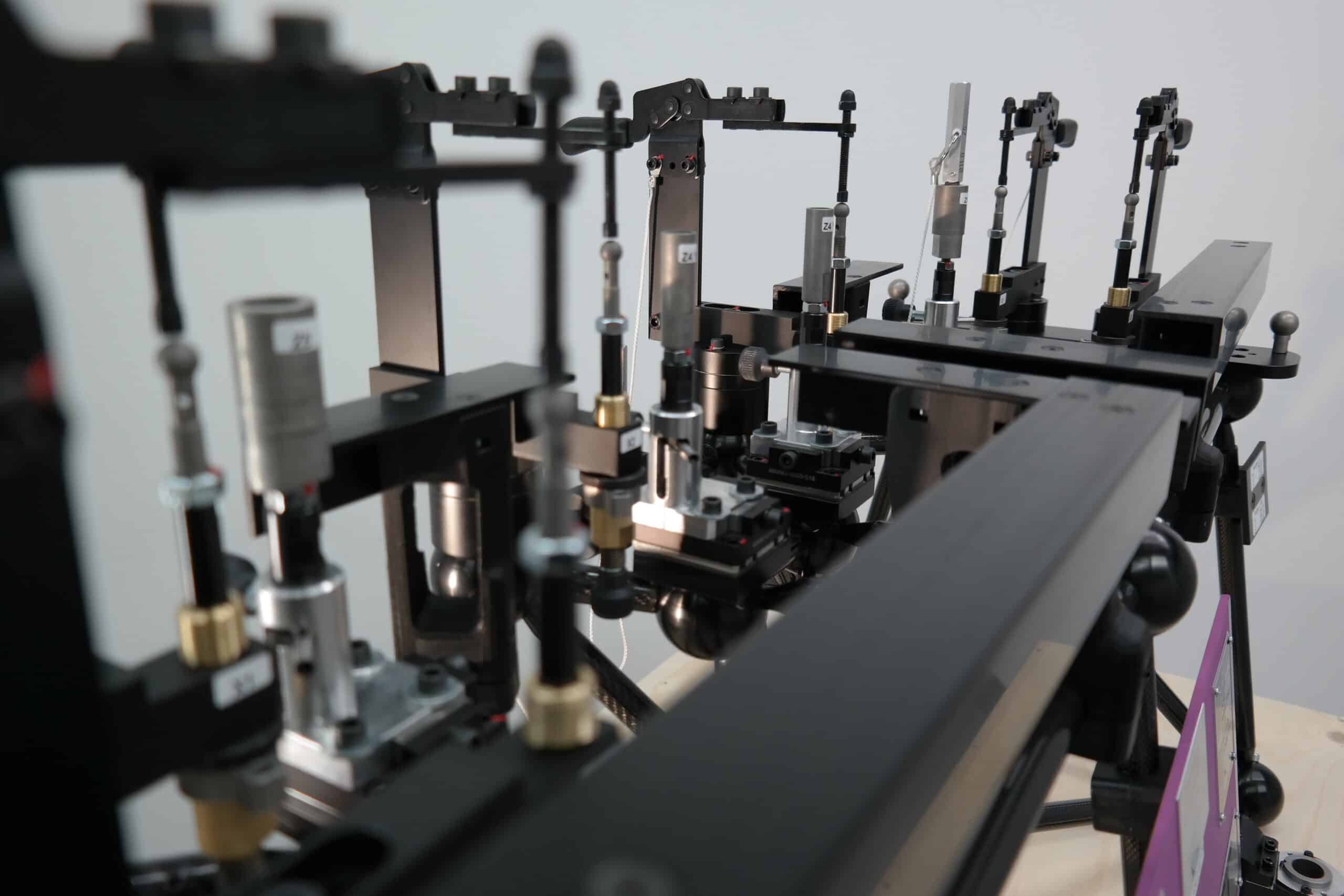

2. Control gauges

For each work step, we produce exactly the control gauge you need for optimum testing in your process.

True to detail and absolutely precise. CNC measuring machines are available for monitoring and gauge capability testing.

3. Cubing & Simulation

Gap dimensions, design lines, component appearance … the guarantors of visible and tangible quality. A cubing model makes it possible to test this in the clearest form in the interplay of all factors. We regard these models as the premier class of test equipment construction and manufacture these zero models from aluminum and steel with the utmost care and precision. It goes without saying that we take all customer-specific requirements into account.

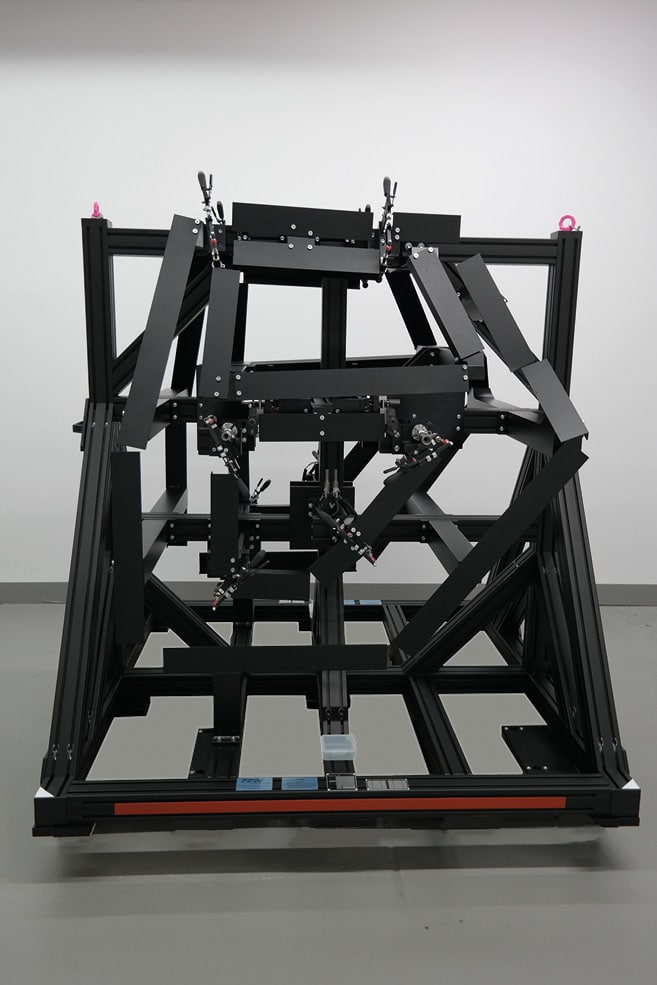

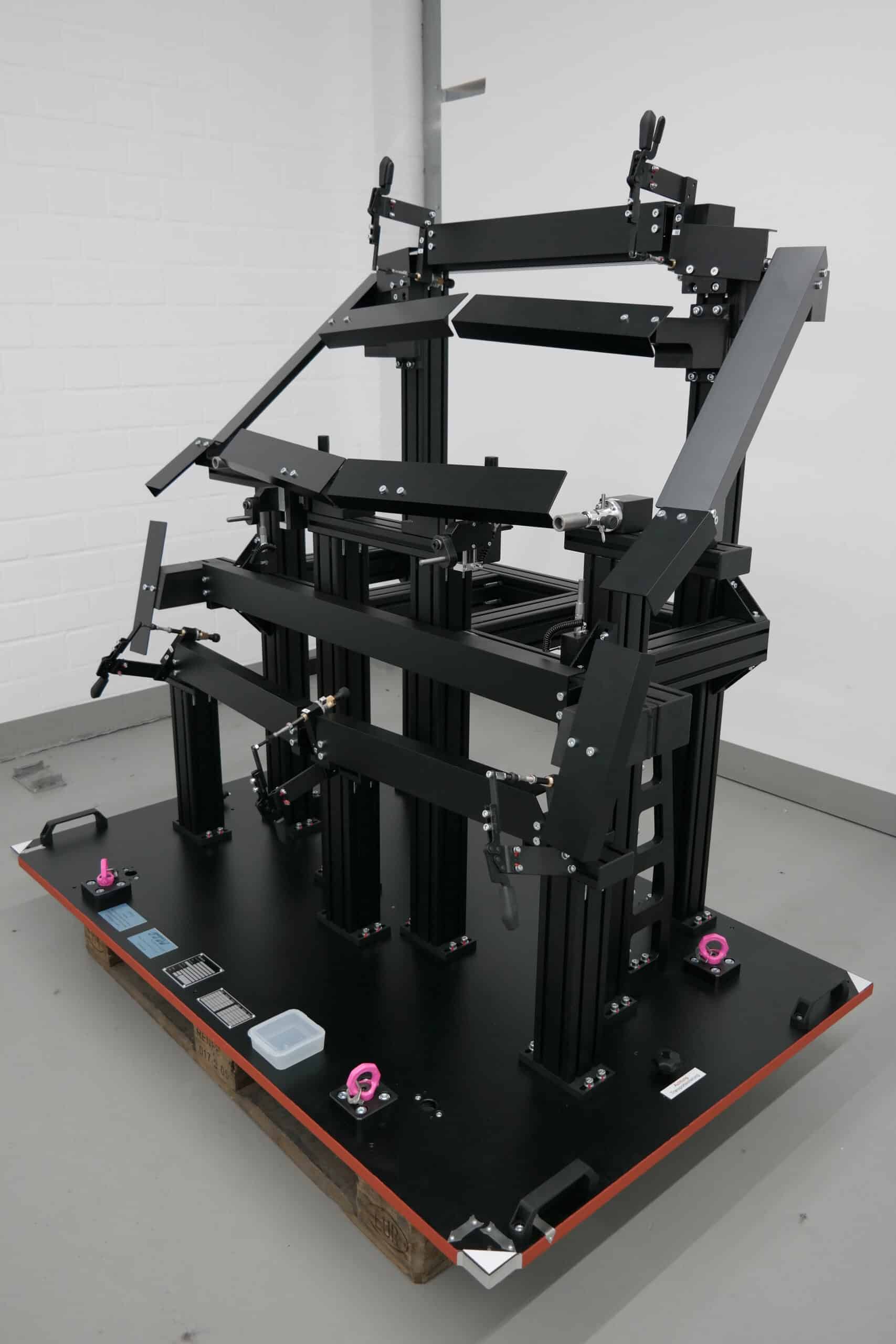

4. Outer and joining master blocks

All visible body parts and body-in-white components are picked up on our external and joining master jigs according to the specified alignment system. To simulate production and installation tolerances, all individual parts can be moved freely in space using 2D and 3D adjustment units. The joint and tolerance pattern can thus be optimally evaluated. Furthermore, the planned joining sequence can be validated for subsequent production.